Description

"Jin?Tai" stamping dies and cold heading dies

Features:

Choose the appropriate grade based on the customer's actual usage and the material being processed. With various tungsten steel stamping die grades, it can meet the requirements of different applications, complete specifications, precise blank dimensions, reduce processing volume, and improve efficiency and cost-effectiveness.

Performance:

Using 99.95% high-purity raw material tungsten carbide powder and cobalt, the hardness of cold heading dies reaches above HRA88, bending strength exceeds 2400, with excellent red hardness, high wear resistance, high elastic modulus, high bending strength, and durable impact resistance.

Applications:

Suitable for cold heading and cold extrusion of standard parts made of copper, aluminum, steel, alloy steel materials, such as screws, rivets, etc. Common varieties include flat head cold heading dies, recessed head cold heading dies, one-sequence punch and die, reduction rod dies, etc.

Stamping Dies Cold Heading Dies

Features:

Choose the appropriate grade based on the customer's actual usage and the material being processed. With various tungsten steel stamping die grades, it can meet the requirements of different applications, complete specifications, precise blank dimensions, reduce processing volume, and improve efficiency while reducing costs.

Performance:

Using 99.95% high-purity raw material tungsten carbide powder and cobalt, the hardness of cold heading dies reaches above HRA88, bending strength exceeds 2400, with excellent red hardness, high wear resistance, high elastic modulus, high bending strength, and durable impact resistance.

Applications:

Suitable for cold heading and cold extrusion of standard parts made of copper, aluminum, steel, alloy steel materials, such as screws, rivets, etc. Common varieties include flat head cold heading dies, recessed head cold heading dies, one-sequence punch and die, reduction rod dies, etc.

Corrosion resistance is critical when it comes to maintaining surface quality and long-lasting performance. Our tungsten carbide dies are specifically designed to effectively resist corrosion. These molds are exceptionally resistant to corrosion and will keep your surfaces in pristine condition, ensuring a perfect finish every time. You can trust our molds to stand the test of time and deliver superior results with every use.

Whether it's a specialized design, unique size or specific performance requirements, our team of experts is dedicated to delivering molds that exceed your expectations.

Corrosion resistance is critical when it comes to maintaining surface quality and long-lasting performance. Our tungsten carbide dies are specifically designed to effectively resist corrosion. These molds are exceptionally resistant to corrosion and will keep your surfaces in pristine condition, ensuring a perfect finish every time. You can trust our molds to stand the test of time and deliver superior results with every use.

Whether it's a specialized design, unique size or specific performance requirements, our team of experts is dedicated to delivering molds that exceed your expectations.

Unleash the precision prowess of Tungsten Carbide Molds! As a cross-border e-commerce connoisseur, you've arrived at the perfect destination for top-of-the-line Tungsten Carbide Molds that excel in diverse molding applications, ensuring unmatched accuracy and durability.

Meticulously engineered with unparalleled expertise, our Tungsten Carbide Molds exhibit extraordinary hardness and wear resistance, making them the ultimate choice for molding tasks in industries like automotive, electronics, and more. Trust these molds to deliver flawless results and extended lifespan, revolutionizing your molding processes.

Beyond their exceptional toughness, our Tungsten Carbide Molds demonstrate remarkable heat resistance, guaranteeing consistent performance even under the most demanding high-temperature conditions. Experience their ability to maintain precise shapes and dependability, empowering you to optimize productivity and reduce production costs.

At JINTAI, we take immense pride in delivering products that exceed the highest quality standards. Each Tungsten Carbide Mold undergoes rigorous testing, ensuring uniformity and excellence, enabling you to achieve impeccable results in your molding projects.

Embrace efficiency and cost-effectiveness with our premium Tungsten Carbide Molds, and gain a competitive edge in your industry. Partner with us today to experience the unparalleled performance these molds bring to your molding operations.

Choose JINTAI for reliable, high-performance Tungsten Carbide Molds, and witness their true potential in elevating your business to new heights. Place your order now and harness the power of our top-tier molding solutions.

Grade List

| Grade | ISO Code | Physical Mechanical Properties (≥) | Application | ||

| Density g/cm3 |

Hardness(HRA) | T.R.S N/mm2 |

|||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Suitable for precision machining of cast iron and non-ferrous metals. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Suitable for precision machining and semi-finishing of cast iron and non-ferrous metals, as well as for processing of manganese steel and quenched steel. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Suitable for semi-finishing and rough machining of cast iron and light alloys, and can also be used for rough machining of cast iron and low alloy steel. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Suitable for inlaying rotary impact rock drilling and rotary impact rock drilling bits. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Suitable for inlaying chisel-shaped or conical teeth bits for heavy-duty rock drilling machines to tackle hard rock formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Suitable for tensile testing of steel bars and steel pipes under high compression ratios. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Suitable for making stamping dies. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Suitable for making cold stamping and cold pressing dies for industries such as standard parts, bearings, tools, etc. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Suitable for precision machining and semi-finishing of stainless steel and general alloy steel. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Suitable for semi-finishing of stainless steel and low alloy steel. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Suitable for precision machining of iron-based, nickel-based high-temperature alloys, and high-strength steel. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Suitable for heavy-duty cutting of steel and cast iron. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Suitable for precision machining and semi-finishing of steel and cast iron. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Suitable for precision machining and semi-finishing of steel and cast iron, with moderate feed rate. YS25 is specially designed for milling operations on steel and cast iron. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Suitable for heavy-duty cutting tools, providing excellent results in rough turning of castings and various steel forgings. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Suitable for inlaying rotary impact rock drilling bits and drilling in hard and relatively hard rock formations. |

Order Process

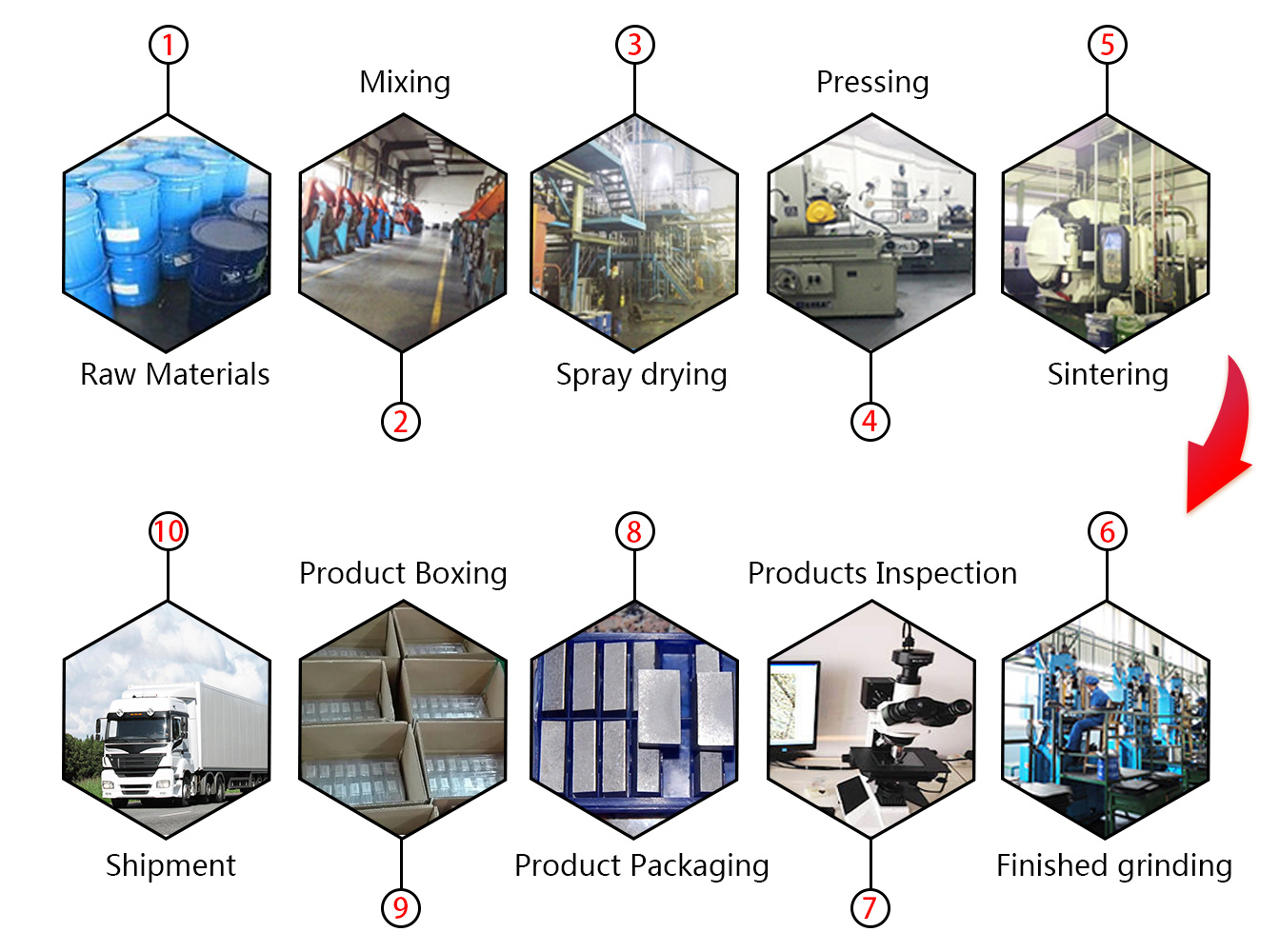

Production Process

Packaging