One of the high-quality cemented carbide strips is based on the WC-TiC-Co cemented carbide, which has the TaC (NbC) precious metal component that can significantly improve the high-temperature hardness and high-temperature strength of the alloy, and the selected 0.4um ultra-fine grain alloy powder is made by vacuum low-pressure sintering, and its hardness is as high as 993.6HRA; Ideal for high-quality carbide knives made of particleboard and stainless steel.

Characteristics of tungsten carbide strips: Tungsten carbide strips are WC-TiC-TaC (NbC) Co cemented carbide with 0.5 ultra-fine grains, which have high hardness and high heat resistance, anti-bonding, anti-oxidation ability T and anti-diffusion ability, and also have the characteristics of significantly increasing the resistance to crescent crater wear and flank wear and good weldability, ST12F cemented carbide strip has excellent comprehensive properties, mainly used for processing high-speed steel, tool steel, cold-hardened cast iron, glass fiber, High-speed carbide cutting tools made of particleboard and stainless steel.

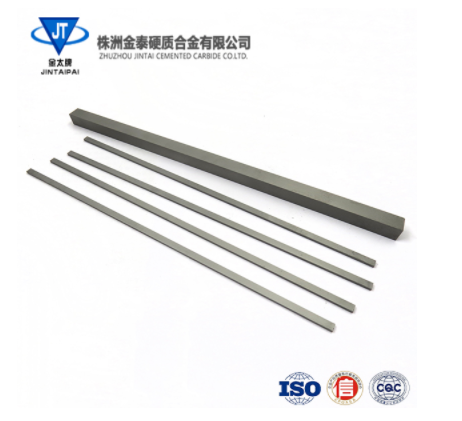

Tungsten carbide strips are mainly made of WC tungsten carbide and Co cobalt powder mixed by metallurgical methods through pulverization, ball grinding, pressing and sintering, the main alloy components are WC and Co, and the composition content of WC and Co in the cemented carbide strips for different purposes is not consistent, and the use range is very wide. Tungsten carbide strips are one of the many materials that are mainly in the shape of bars.

The production process of tungsten carbide strips mainly includes milling→ formula according to the requirements of use→ through wet grinding→ mixing→ crushing→ drying→ after sieving→ adding molding agent→ then drying→ sieving and then preparing mixture→ granulation→ HIP pressing → forming → low-pressure sintering→ forming (billet) flaw detection → packaging → warehousing.

Tungsten carbide strips have excellent red hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, low expansion coefficient, thermal and electrical conductivity similar to iron and its alloys.

Tungsten carbide strip application range:

1. Suitable for dressing and forming knives for cast iron rolls and high nickel-chromium rolls.

2. Suitable for making strippers, stamping dies, punches, electronic progressive dies and other stamping dies.

Post time: Nov-19-2024