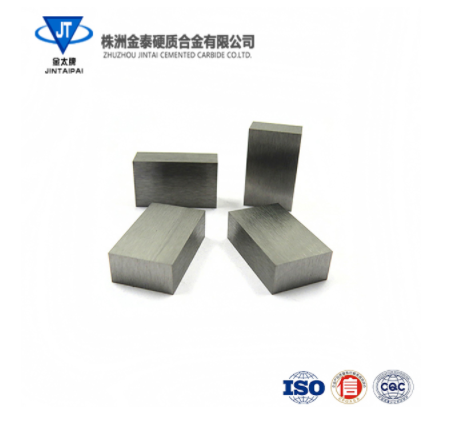

What is carbide plate?

1. The impurity content is very small, and the physical properties of the board are more stable.

2. Using spray drying technology, the material is protected by high-purity nitrogen under fully sealed conditions, which effectively reduces the possibility of oxygenation during the preparation process of the mixture. The purity is better and the material is not easy to become dirty.

3. The density of the board is uniform: It is pressed with a 300Mpa isostatic press, which effectively eliminates the occurrence of pressing defects and makes the density of the board blank more uniform.

4. The plate has excellent density and excellent strength and hardness indicators: using ship low-pressure sintering technology, the pores inside the plate can be effectively eliminated and the quality is more stable.

5. Using cryogenic treatment technology, the internal metallographic structure of the plate can be improved, and the internal stress can be greatly eliminated to avoid the occurrence of cracks during the cutting and forming process of the plate.

6. The material properties of cemented carbide plates for different uses are not consistent. When using them, long carbide strips of appropriate materials should be selected according to the specific uses.

Application scope of cemented carbide plate:

Carbide sheets are suitable for: softwood, hardwood, particle board, density board, non-ferrous metal, steel, stainless steel, good versatility, easy to weld, suitable for processing soft and hardwood.

The use of cemented carbide plates is mainly divided into the following categories:

1. Used to manufacture punching molds. It is used to manufacture high-speed punching dies and multi-station progressive dies for punching copper, aluminum, stainless steel, cold-rolled plates, EI sheets, Q195, SPCC, silicon steel sheets, hardware, standard parts, and upper and lower punching sheets.

2. Used to manufacture wear-resistant cutting tools. Such as carpenter’s professional knives, plastic breaking knives, etc.

3. Used to manufacture high-temperature-resistant parts, wear-resistant parts, and anti-shielding parts. Such as machine tool guide rails, ATM anti-theft reinforcement plates, etc.

4. Used to manufacture corrosion-resistant parts for the chemical industry.

5. Radiation protection and anti-corrosion materials for medical equipment.

Post time: Oct-11-2024